Specifications for Cutting Tool Types

It is recommended that you use carbide cutting tools when working with SIGN·FOAM. These are more expensive to purchase initially, but they return value over time and hold up to the heat generated when cutting SIGN·FOAM. Do not use a hot wire or laser cutter; these create unpredictable results and may cause an ignition hazard. See the P.P.D.S for more information.

Tips for Cutting Tools

Your shop is likely equipped with these items: a table saw, band saw, radial saw, a jigsaw, scroll saw, reciprocating saw or other hand tools.

- The table saw: A mainstay of every serious shop is the most reliable way of making the straight cuts needed for most projects. Your choice of blade is not critical here, any blade on the table will cut SIGN·FOAM quickly and easily. A built in fence guide makes it easier to use.

- The circular saw: Valuable and portable, used for times when a table saw is not available. You will want to employ a fence or guide to keep the blade running true.

- A band saw: Easily cuts curves in SIGN·FOAM for letters and appliques. Using a wider blade makes tight curves more challenging, but it keeps the blade running true. A band saw can cut very thick pieces of SIGN·FOAM.

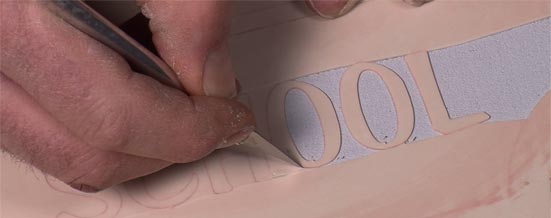

- A quality saber saw: Invaluable when machining SIGN·FOAM and great for cutting curved pieces or to cut a set of letters. This performs many of the same functions as the more expensive band saw and gives you the flexibility to free hand cut any number of curved shapes or to use a fence or guide to make straight cuts.

Tips for Minimizing "Blade Wander" when Cutting

Using smooth cutting actions and a large tooth blade helps minimize blade wander. Wood grain has a tendency to grab the blade; SIGN·FOAM has no grain and will cut true. The key is to cut slow and easy and always outside the line. An operator may attempt to push through the material too fast; but this will cause blade wander so take your time.